Decommissioning

At Astrimar, we are specialist providers of innovative, technology-led, engineered decommissioning solutions for the energy sector. Leveraging deep expertise in complex subsea, oil and gas infrastructure and offshore renewables, we design and deliver bespoke tools and methodologies while mitigating the risks associated with ageing assets, helping operators retire them safely, efficiently, and in full compliance with industry standards.

Well Plug & Abandonment (P&A) Expertise

Industry best practice increasingly demands a risk-based approach for well P&A to address well-specific challenges and support adoption of new technologies. Astrimar offers a proven process to support operators in designing barriers, that aligns with OEUK Well Decommissioning Guidelines (Issue 7), while managing uncertainty, and demonstrating ALARP (As Low As Reasonably Practicable) to the regulator. The approach taken is essential for complex wells, deviations from standard guidelines, or the use of new plugging technologies. It involves the application of key assurance tools and technical processes, including:

Well Barrier Qualification Assessments – Verifying barrier integrity for safe abandonment using use of Monte Carlo Simulation to model all P&A design parameters as statistical distributions, reflecting the impact of uncertainty in the outputs.

Well Barrier Integrity Assurance – Astrimar’s STEMflow tool has been developed specifically to support the industry in understanding the technical risks associated with different well P&A designs. It provides a unique, quantified insight for evaluating conventional and new plug technologies, ensuring risk-based decision-making for optimal design.

Risk & Reliability Assurance – We utilise best practice methods to evaluate different barrier options and associated technical risks, including Failure Analysis (FMEA, FMECA, FTA, Event Tree Analysis) and Technical Risk Categorization, ensuring risk reduction is As Low As Reasonably Practicable (ALARP).

Technology Qualification – Validating tools and techniques for safe and effective operations. We apply qualification best practice to support technology assurance for novel P&A plug technologies.

Well P&A Technology Qualification Framework - Astrimar has collaborated with NZTC, and the wider industry, to develop the Well P&A Technology Qualification Framework, to help address the risks associated with adoption of new barrier technologies by providing a consistent, structured and best-practice based approach to their qualification and deployment. The framework enables operators, technology providers and regulators to work from a shared reference point to assess performance, manage risk and support confident decision-making.

Engineered Solutions for Complex Decommissioning Challenges

The safe decommissioning of ageing oil and gas assets poses a wide variety of challenges, including limited legacy documentation, equipment degradation, and tooling gaps. Astrimar delivers innovative, bespoke solutions to these complex problems, ensuring safe, timely, and cost-effective asset retirement.

When standard approaches aren’t enough, we provide integrated engineering and technical assurance tailored to your project needs:

Addressing Legacy Challenges (Data Gaps & Degradation):

Reverse Engineering for Legacy Structures – Creating accurate 3D CAD models from original 2D drawings, laser-scan point-cloud data, ROV footage, or diver survey data to overcome missing or degraded documentation and reflect as-built conditions.

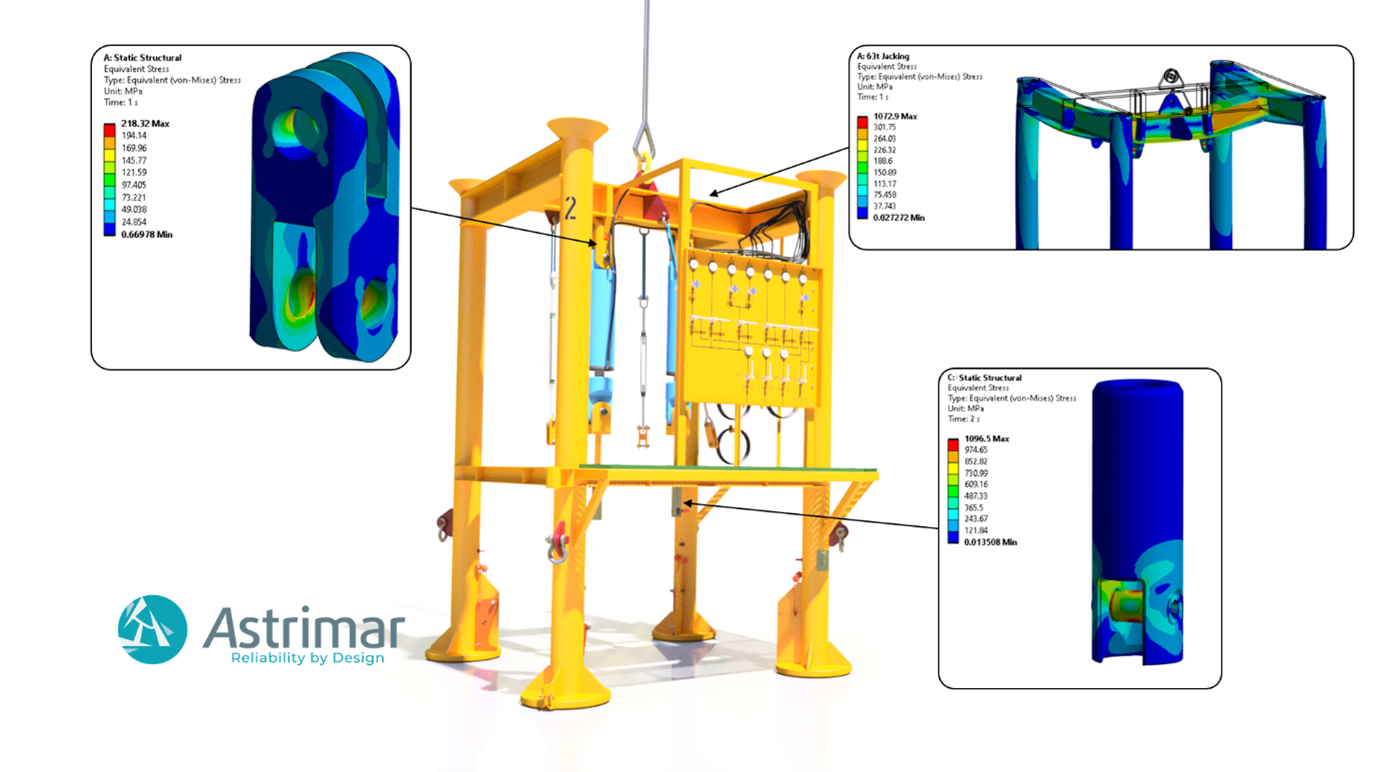

Structural Integrity Analysis – Performing Advanced FE Analysis (Finite Element) and Advanced Numerical Analysis to assess damaged and degraded equipment (due to fatigue, corrosion, erosion, or impact) and develop and define safe removal methodologies.

Integrated Design, Analysis, and Verification – Ensuring technical rigour for all solutions.

Bespoke Tooling and Operational Execution:

Tooling and Equipment Design – Designing and overseeing the manufacture of bespoke decommissioning tools, such as custom lifting frames and jacking systems, to interface with unique or non-standard legacy equipment.

Removal and Lifting Studies – Providing hydrodynamics and complex CFD (Computational Fluid Dynamics) simulations to develop verified, safe, and efficient asset recovery and lifting procedures.

Procedure Development & Visualisation – Creation of detailed decommissioning procedures, including storyboard models and animations, to clearly communicate and assure complex operational steps.

Project Realisation and Assurance:

Concept-to-Completion Delivery – Taking projects from feasibility studies and innovation realisation through to safe execution.

Reliability by Design – Building resilience and safety into every stage of the solution to ensure “right first time”.

Project Management & Technical Assurance – Ensuring quality, safety, and timely delivery across all phases.

Life-of-Field Extension – Astrimar can also offer bespoke solutions for life-of-field extension, enabling assets to remain operating safely for longer and delaying the need for decommissioning.